What are prosthetic eyes made of? These essential medical devices primarily use materials such as acrylic, glass, and silicone to replicate the function and appearance of a natural eye. Quick to the point, this article will unpack the characteristics that make these materials ideal for prosthetics, the benefits they bring to wearers, and how ocularists craft them into lifelike ocular prostheses.

Key Takeaways

- Prosthetic eyes are primarily made from materials such as acrylic, glass, and silicone, with acrylic being the most commonly used due to its customizability and realistic appearance.

- The manufacturing process of prosthetic eyes is intricate, involving ocularists who take impressions and measurements to ensure a custom fit, and it includes the crafting of the iris and fitting adjustments that may take multiple appointments over 1-2 weeks.

- Advancements in prosthetic eye technology, such as electronic implants and 3D printing, are promising improved outcomes and customization, while regular maintenance and emotional support are essential for individuals adapting to prosthetic eyes.

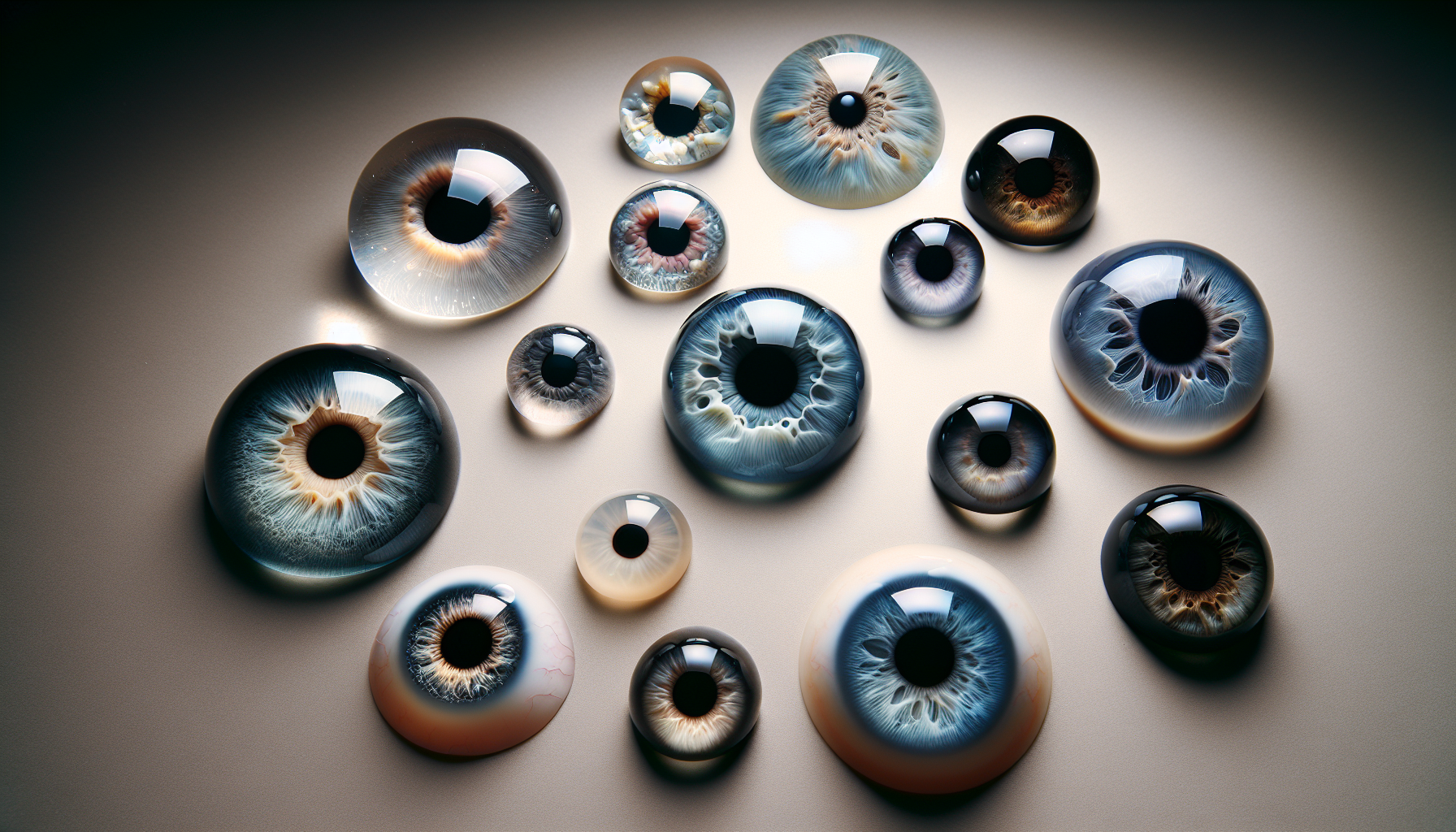

Materials Used in Prosthetic Eyes

Various prosthetic eyes made from different materials as imagined by AI – For illustration only-Image created by AI

Prosthetic eyes, often called artificial eyes or ocular prostheses, are typically crafted from a range of materials such as glass, acrylic, and silicone. Each of these materials has its own unique properties that allow the prosthetic eye to mimic the appearance and movement of a natural eye. The choice of material is crucial, as it determines the durability, comfort, and aesthetics of the ocular prosthesis.

Acrylic is the predominant material used in most ocular prostheses today. Still, a small number of prostheses are crafted using cryolite glass, each offering its own unique advantages. We’ll explore more about these materials in the following subsections, starting with the traditional option – the glass eye.

Glass Eye

Glass has been used in the creation of prosthetic eyes for centuries. The production process involves shaping a glass tube into the desired shape of the eye and then placing a ball made of inert material such as plastic, glass, or silicone inside the eyeball. This process takes approximately 30-40 minutes and aims to replicate natural eye movement.

Despite being an older option, glass eyes offer a unique set of benefits. They:

- Enable the body to maintain proper function after the loss of an eye

- Enhance the aesthetic appearance of individuals who have experienced eye loss

- Provide comfort to the wearer as they are lighter than other types of prosthetic eyes.

The majority of custom ocular prostheses, such as glass prosthetic eyes, are manufactured using PMMA (polymethyl methacrylate) or acrylic, allowing for a custom eye tailored to the patient’s needs.

Acrylic Eye

Acrylic, being the most commonly used material, has several advantages that make it a preferred choice for prosthetic eyes. It provides comfort, allows for effective customization techniques, and offers an aesthetic appeal that closely resembles a natural eye. The process for achieving this natural appearance is meticulous – employing pigments for the iris and sclera, which are subsequently colored and polished to closely replicate the natural eye color, resulting in a realistic appearance.

Despite these advantages, there are a few drawbacks to consider. Acrylic prosthetic eyes require periodic replacements due to anatomical changes in the eye socket and there’s a possibility for the material to discolor over time. However, with proper care and maintenance, these issues can be mitigated.

Silicone Eye

Silicone, a more recent addition to the materials used in the production of prosthetic eyes, offers its own unique set of advantages. A silicone prosthetic eye is created by forming a mould and taking an impression of the eye socket. Then, a silicone ball is inserted into the mould, shaping it into the eyeball of the prosthesis.

Beyond just forming the eyeball, silicone is also used to fabricate the eyelids and adjacent tissue of the orbital prosthesis. The ocular component of the eye is encapsulated within the silicone, creating an integrated prosthesis. An orbital prosthesis is tailored to restore the eyelids and socket volume aesthetically after an exenteration, providing structural support to the affected area.

The Manufacturing Process of Prosthetic Eyes

From the initial consultation to the final fitting, the process of creating a prosthetic eye is a meticulous one, carried out by professionals known as ocularists. These specialists are responsible for:

- Ascertaining the dimensions, form, and placement of the prosthetic eye

- Using premium acrylic materials for crafting the prosthetic

- Adorning the prosthetic with intricate paintwork to replicate the natural appearance of an eye

In the case of glass prosthetic eyes, the process can involve creating a ‘moulded prosthesis’ that is specifically custom-molded to fit the individual’s eye socket or a ‘cosmetic shell’ intended to enhance the cosmetic appearance of an existing eye. We will explore the stages of the manufacturing process in further detail.

Initial Consultation

The journey of creating a prosthetic eye begins with an initial consultation, where the ocularist takes measurements using an impression or a modified impression method, assessing the horizontal and vertical dimensions of the eye socket. The ocularist also reviews the patient’s medical condition and surgical history, including any prior surgical procedure, assessing the eye socket, and taking specific measurements to determine the appropriate size and shape for the prosthetic eye. The shape is then processed and adjusted to expose the iris on white acrylic.

During the consultation, the ocularist may also discuss the recommended replacement frequency of the prosthetic eye, the protocols for removing and cleaning the prosthetic eye, and the frequency of its removal. This comprehensive process ensures that the prosthetic eye will be a comfortable and aesthetic fit for the individual, following a surgical eye removal procedure.

Crafting the Prosthesis

Once the initial consultation is complete, the crafting of the prosthesis begins. The ocularist uses tools such as:

- oil-based clay

- wax

- plaster of paris

- alginate

to construct and customize the ocular prosthesis. They create socket impressions and oversee the proper fitting and maintenance of the prosthetics.

One of the most important aspects of crafting the prosthesis is creating the iris. The iris in a prosthetic eye is meticulously crafted as a thin disk from biocompatible medical-grade silicone, tailored specifically for each patient. It is meticulously color-matched using photos of the patient’s natural eye to ensure a lifelike appearance.

The whole crafting process typically entails several appointments spanning over a period of 1-2 weeks, with each session lasting around 1-2 hours.

Fitting and Adjustments

The final step in the process is the fitting and adjustment of the prosthetic eye. This phase ensures that the prosthetic eye is comfortable, remains in its intended position, and offers appropriate movement. However, the fitting and adjustment process is not without its challenges. Individuals may experience issues such as teary eyes, mucous discharge from the socket, discomfort, and other physical symptoms like trouble focusing and muscle tension. However, with the expertise of the ocularist, these issues can be addressed and resolved, ensuring a comfortable and well-fitted prosthetic eye.

Advancements in Prosthetic Eye Technology

The field of prosthetic eyes is not static but continues to evolve with the advent of new technologies. Recent advancements in prosthetic eye technology include the development of electronic implants and the use of 3D printing, both promising to revolutionize the way prosthetic eyes are created and used.

Electronic implants aid in the restoration of vision by converting signals into electrical impulses through the use of electrodes on the implanted chip. These impulses then stimulate cells in the retina that are connected to the optic nerve. We will explore these exciting advancements in more detail in the subsequent subsections.

Electronic Implants

Electronic implants in prosthetic eyes serve to:

- Convert visual information into patterns of electrical stimulation

- Stimulate the retina to produce artificial vision

- Deliver small electrical pulses to the remaining visual cells in the eye

- Improve light sensitivity

- Generate artificial vision

These eye implant devices operate by delivering small electrical pulses to the remaining visual cells in the eye, thereby improving light sensitivity and generating artificial vision.

The process of obtaining an electronic implant in a prosthetic eye includes:

- Enucleation, in which the remaining eye muscles are connected to an orbital implant.

- Placing the electronic implant.

- Fitting a prosthetic eye over the implant.

The effectiveness of electronic implants in prosthetic eyes, including artificial eye technology and porous implant applications, is currently being investigated, with preliminary results showing potential in providing artificial vision.

3D Printing

The advent of 3D printing technology has brought about significant changes in the manufacturing of prosthetic eyes. This technology enables:

- The generation of 3D scans of the eye socket

- Color-calibrated images of the healthy eye for a personalized prosthesis

- The ability to produce prostheses in large quantities

- Predetermined iris colors

3D printing improves the fit of prosthetic eyes by:

- Providing a wider range of options in optic sizes

- Adjusting the shape of the intraocular lens to minimize dysphotopsia

- Utilizing precise 3D scans of the eye socket for an accurate fit

This technology also contributes to reducing the necessity for subsequent adjustments in surgical procedures by enabling detailed preoperative planning based on the patient’s specific anatomy.

Caring for Your Prosthetic Eye

Once a prosthetic eye has been fitted, proper care and maintenance are crucial for extending its lifespan and ensuring comfort. This involves regular cleaning and hygiene practices and attending regular checkups with an ocularist.

Keeping the prosthetic eye clean is paramount. It is recommended to clean a prosthetic eye once per month using warm water and mild soap or baby shampoo, avoiding alcohol-based cleaning products. It is important to ensure that all sides of the prosthetic eye are thoroughly washed.

We will further discuss the care and maintenance of a prosthetic eye in the following subsections.

Cleaning and Hygiene

Regular cleaning of a prosthetic eye is crucial for its maintenance. Here are the steps to follow:

- Rinse the prosthetic eye under a stream of warm water.

- Wash it with mild soap if needed.

- Ensure thorough rinsing.

- Dry it with a soft cloth or tissue before reinsertion.

Remember, do not use alcohol-based cleaning products or improper detergents as they can potentially damage the prosthetic eye.

In addition to regular cleaning, it’s also important to handle the prosthetic eye with care to avoid damage. Always ensure to wash your hands with a mild soap before handling the prosthetic eye and avoid cleaning products that contain alcohol or solvents.

Regular Checkups

Regular checkups with an ocularist are crucial for maintaining a good condition of the prosthetic eye. These visits allow for professional cleaning that removes stubborn deposits and prevents bacterial infiltration, which can affect the prosthetic eye.

During these checkups, modifications to the prosthetic eye may also be made. These include alterations to the color, size, or fit to ensure that the prosthetic closely resembles natural movements and appearance. In some cases, if necessary, a prosthetic eye can be replaced during a regular checkup.

The Emotional Impact of Prosthetic Eyes

The loss of an eye and the subsequent fitting of a prosthetic eye can have a profound emotional impact on an individual. The process may evoke a myriad of complex emotions, including:

- Fear

- Anxiety

- Sadness

- Anger

Apart from the physical adjustments, the emotional journey is equally significant and needs to be addressed with care and understanding.

Acknowledging these emotions and seeking help is a critical part of the healing process. Recognizing that grieving the loss of an eye is perfectly normal is a key step. With time, support, and the right resources, leading a fulfilling life with a prosthetic eye is achievable.

Coping with Loss

The loss of an eye is a significant event that can trigger a range of emotions. Coping with such a loss can involve feelings of grief, anger, and depression, and it’s crucial to acknowledge and address these emotions.

Therapies such as lifestyle adjustment courses, therapeutic counseling for vision loss, and learning to manage and live with one eye are typically suggested for managing the loss of an eye.

Family and friends can also provide support by maintaining an approachable, genuine, and supportive demeanor, promoting self-confidence, acknowledging advancements, and fostering self-sufficiency.

Support Resources

Coping with the loss of an eye and adjusting to a prosthetic eye can be a daunting process. However, you’re not alone. There are numerous support resources available for individuals with prosthetic eyes. Professional counseling and support groups are intended to assist individuals in adapting to prosthetic eyes, and there may be financial assistance programs available for those in need.

Online communities also provide a platform for sharing experiences, receiving emotional support, and acquiring guidance on navigating the psychological aspects of this life change. Furthermore, family and friends can provide assistance by engaging in support groups such as ArtEyes, a community for individuals with artificial eyes, and collaborating with ocularists to create a buddy system, especially beneficial for parents with children who have prosthetic eyes.

Summary

Prosthetic eyes have come a long way in both their creation and functionality. From the various materials used, like glass, acrylic, and silicone, to the meticulous crafting process and the importance of proper care and maintenance – every aspect contributes to the lifelike appearance and functionality of these artificial eyes. Advances in technology, such as electronic implants and 3D printing, promise a future where prosthetic eyes may even restore some form of vision. While the physical journey of acquiring and maintaining a prosthetic eye is significant, the emotional journey is equally important, and acknowledging and addressing these feelings is crucial to the overall adjustment process.

Frequently Asked Questions

What are prosthetic eye made of?

A prosthetic eye is generally made of hard, plastic acrylic, shaped like a shell to match the patient’s natural eye. This material is the most common choice for modern prosthetic eyes.

What do people with prosthetic eyes see?

People with prosthetic eyes can distinguish between light and dark and recognize shapes, but they do not fully restore sight.

Can prosthetic eyes cry?

Yes, you can still cry with a prosthetic eye, as the eyelids still produce tears. So, even with a prosthetic eye, you can continue to produce tears.

How often should a prosthetic eye be cleaned?

You should clean your prosthetic eye once per month using warm water and mild soap or baby shampoo, and avoid alcohol-based cleaning products. This helps to maintain its hygiene and appearance.